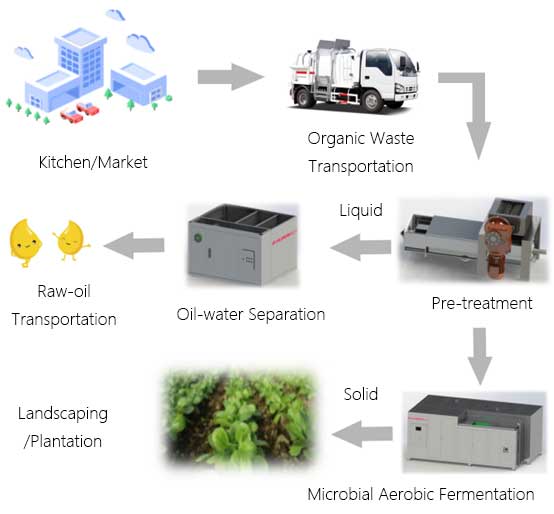

Using organic waste such as kitchen/fruit and vegetable as raw materials, it can be quickly decomposed by comprehensive treatment technologies such as press dehydration, oil-water separation, and microbial aerobic fermentation.

Using organic waste such as kitchen/fruit and vegetable as raw materials, it can be quickly decomposed by comprehensive treatment technologies such as press dehydration, oil-water separation, and microbial aerobic fermentation.

Using organic waste such as kitchen/fruit and vegetable as raw materials, it can be quickly decomposed by comprehensive treatment technologies such as press dehydration, oil-water separation, and microbial aerobic fermentation. The residence time of materials in the fermentation chamber should not less than 5 days. After the equipment is set with operating parameters, it can be automatically operated without manual operation. The product is based on the principle of aerobic fermentation and can process organic waste such as kitchen waste, wet waste, and garden waste in communities, towns, and other places in the spot, reducing secondary pollution. The waste reduction rate reaches 90% and above. The output meets the “Organic Fertilizer NY525-2012” standard and can be used for soil improvement, landscaping, etc. to fully achieve waste reduction, recycling, and harmlessness treatment. The product has a high degree of automation, easy operation, and a wide range of applications. Compared with the traditional composting method, it has the advantages of fast fermentation and small footprint.

Barrel feeding series products: including daily processing capacity of 2 tons, 3 tons and 5 tons, etc. Available for customized.

Truck unloading series products: including daily processing capacity of 5 tons, 10 tons, and 20 tons, etc. Available for customized.

The large effective volume of the fermentation chamber can ensure the residence time of the materials to fully ferment, guarantee the performance indicators of the output, enhance the output fertilizer value and effect; at the same time, the design of the sub-bin in the fermentation chamber effectively avoids the mixing of materials in different fermentation stages, preventing the output from “half-ripe” condition.

In addition to sorting, crushing, dehydrating, conveying, the equipment is additionally equipped with a water washing process, which plays the role of oil and salt removal, greatly reducing the oil and salt content of the material, ensuring the normal growth of microorganisms, and generating high-quality fermentation products.

It can realize continuous feeding and discharge for 24 hours without any time limit. Timed ventilation and aeration to avoid the acidification of the fermented products caused by partial anaerobic and improve the fermentation effect.

According to the needs of the project, the site and remote monitoring system can be configured to monitor the site situation in real-time through the computer and mobile terminal to realize the visualization of site operations.

The equipment adopts electric heating (water circulation) heating technology to prevent the temperature from being too high and is equipped with heating overload protection, which is safe and reliable.