The practical sewage suction truck developed by FULONGMA has technical performance indicators that meet or exceed similar domestic products. It is mainly used for pumping sludge, feces, or petrochemical sewage tank sludge in sewers, rain wells, septic tanks, and various ditches. Suction, discharge, and transportation, suitable for small streets, sub-streets, residential areas, and other road sections.

1. Detailed description of sewage suction truck

Dongfeng 8-ton sewage suction truck chassis configuration: wheelbase 3800, 2030/single row, engine CY4SK261, 170 horsepower, Wanliyang 7-speed gearbox, 825R20, front and rear axle 3.5/7.5, 232 double-layer beams, rotating, clutch assist, Exhaust brake, air-conditioning electric window central control lock, ABS Dongfeng sewage suction vehicle top configuration: the tank body is cylindrical, made of 5mm thick high-quality carbon steel plate of Wuhan Iron and Steel, with a dirt suction window on the front of the tank, and a handwashing device. Lifting device, a 5-meter sewage suction pipe, a variety of colors for the tank body, and the rest are made according to the standard configuration in the factory. The vehicle is equipped with a high-power vacuum sewage suction pump and a high-quality hydraulic system. The head of the tank body is die-casted once, the tank body can be opened behind, and the double top is self-unloading. The dirt in the tank can be dumped directly through the back cover, and it has the characteristics of high vacuum (more suction than a fecal suction truck), large tonnage, high efficiency, and wider use. (Vertical suction stroke: ≥8 m, working pressure: 8500Pa, theoretical pumping speed: 97L/S, shaft power: ≤10kw, inlet and outlet diameter: 50mm, full tank time: <5 min, full tank time: <4min. The sewage suction truck adopts a high-power vacuum pump, a one-time die-casting head-, thickened pressure-resistant tank, and a double-top hydraulic system. It is a more powerful model than the suction truck.

2. Related pictures of sewage suction truck

3. Details of the sewage suction truck

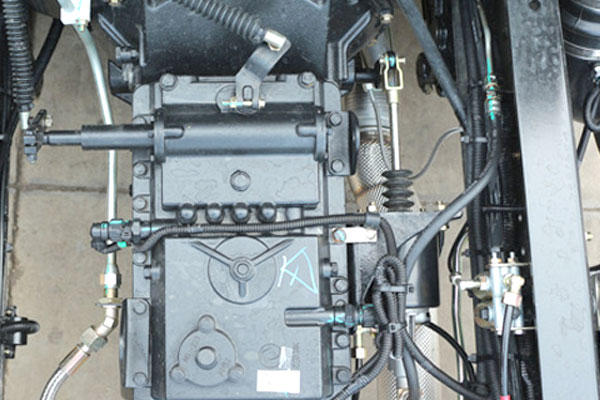

(1) Sewage suction pump: water circulation pump, simple structure, stronger suction, no fear of heat from the pump body, continuous work can choose Yifeng or Weilong oil pump.

(2) Rear self-flow port: the tail self-flow port, with a large caliber, fast self-flow, standard manual ball valve switch, optional hydraulic opening, easy to dump.

(3) Anti-lock braking system (ABS): Give full play to the effectiveness of the brakes, shorten the braking time and distance, which can effectively prevent the vehicle from sliding and flicking during emergency braking, and has good driving stability and steering maneuverability. It can avoid the violent friction between the tire and the ground and reduce the wear of the tire.

(4) Original air brake: Compressed air enters the brake air chamber to lock the wheels, effectively preventing brake failure when the handbrake or drive shaft machine fails, and the brakes are more stable, more accurate, and safer; no pressure when starting uphill.

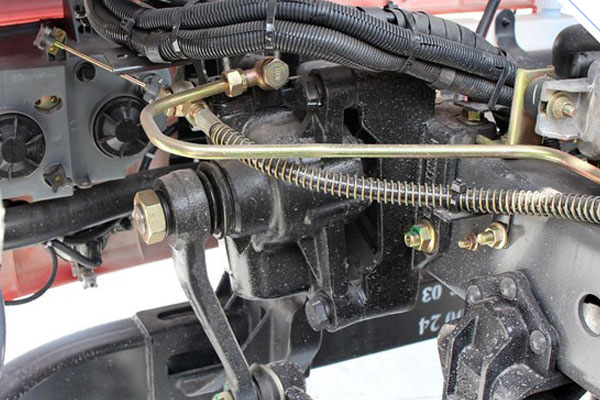

(5) Original hydraulic steering assist: All mechanical parts are connected between the steering wheel and the steering wheel, with precise control, direct road feeling, and rich information feedback; the hydraulic pump is driven by the engine, the steering power is abundant, the technology is mature, and the reliability is high.

(6) National standard emission engine: Yuchai’s 160-horsepower high-torque engine has strong power, worry-free starting at 30% slope, good comfort, low fuel consumption, national sixth emission, and environmental protection standards.

(7) Gearbox: authentic 5-speed gearbox with the auxiliary transmission, high torque, more gears, suitable for complex road sections, easy shifting, worry-free climbing.

(8) Camel 24V battery: leading technology, longer life by more than 12.8%, adding active special substances to the plates, increasing the charging acceptance performance by more than 15.6%; using new technology to improve low-temperature starting performance, -30 degrees environment can meet 6C discharge ;

(9) Optional heating and cooling air-conditioning: optional heating and cooling air-conditioning can adjust the temperature and humidity in the truck, and provide the driver with a comfortable air-conditioning system. It is warm in winter and cool in summer, and you can enjoy it.

4. Maintenance of sewage suction truck

(1) The maintenance of the automobile chassis and supporting pumps shall be carried out in accordance with the corresponding operating instructions.

(2) Before the vehicle is used, it should be run-in according to the requirements of the vehicle instruction manual.

(3) For long-distance transfers, there should be fixed anti-skid devices on the front, rear, left, and right sides of the vehicle, and a gap of more than 200mm should be left around.

(4) Regularly check whether each outlet orifice is clogged, and clean up at a time when the debris is found to be clogged.

(5) After each shift is completed, the oil stains should be cleaned, the pipes should be rolled up neatly, the site should be cleaned, and the doors should be closed and locked.

(6) The vehicle should not be used for a long time or stored in winter. When storing, it should be parked in the carport and wiped clean to avoid exposure to the sun and rain.

5. The correct steps for replacing the hydraulic oil of the sewage suction truck

(1) The cleaning of the chassis: The chassis closest to the ground must have been messed up by mud and sand. Therefore, before cleaning other parts, we must first carry out a comprehensive cleaning of the chassis of the blue brand Dongfeng 5-ton truck-mounted crane with the correct steps to replace the hydraulic oil. After passing the muddy road, the front and rear hub plates of the correct procedure for replacing the hydraulic oil of the sewage suction truck will be stained with yellow mud and small sands. When cleaning, a high-pressure water gun needs to be placed under the hub plate, and the spray direction of the high-pressure water gun is toward the direction of the hub plate, so as to effectively remove the attachment on the hub plate.

(2) Cleaning of the paint surface: After the cleaning of the chassis is completed, we can clean the body of the sewage suction truck in the correct steps of replacing the hydraulic oil. First of all, use tap water to wash the paint surface from top to bottom, the purpose is to wash away the larger volume of sand and stone on the truck body. Use a towel to wipe gently from the roof to the bottom of the truck. Please note that the closer the paint surface to the chassis, the more careful you must wipe it, so as not to scratch the paint on your truck.