FULONGMA pure electric garbage compactor truck is composed of sealed garbage compartments, hydraulic systems, and operating systems. The whole vehicle is fully sealed, and all sewage from the compression, dumping, and compression process enters the sewage tank, which relatively solves the problem of secondary pollution during garbage transportation and avoids inconvenience to people. The key components are imported. The components have the advantages of high pressure, good sealing, convenient operation, etc. Optional rear hanging bucket turning mechanism or garbage bucket turning mechanism.

01. Picture of a pure electric garbage compactor truck

02. Configuration of a pure electric garbage compactor truck

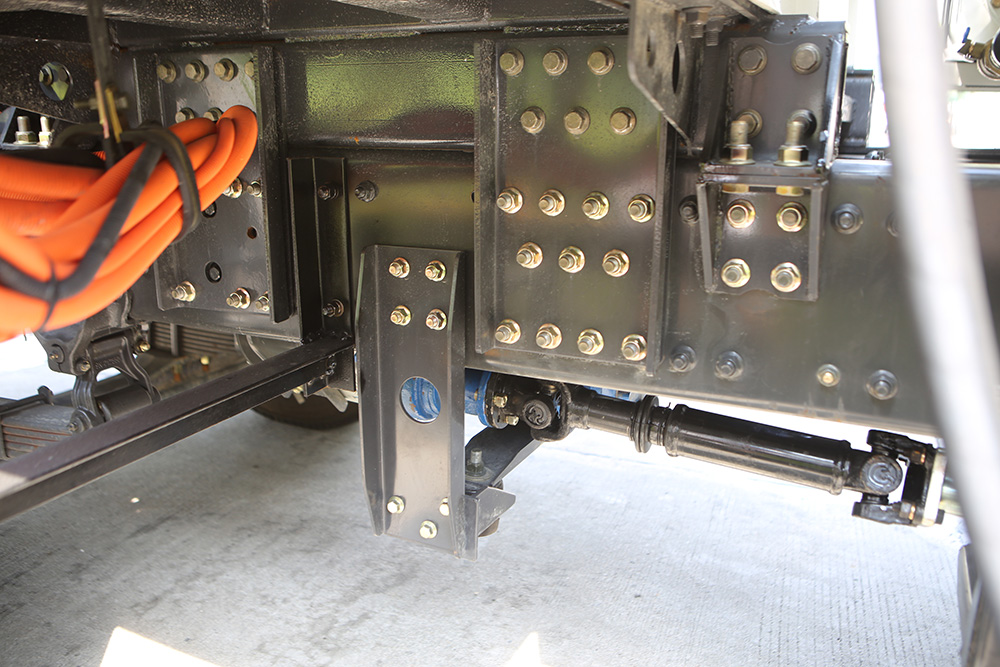

1. Chassis configuration: 3800 wheelbases, Chaochai 170 horsepower, Wanliyang 6-speed gearbox, 245/70R19.5 tubeless tires, 5.5 tons rear axle, 192 double-layer girders, original air conditioning, electric windows, central locking.

2. The top configuration: the box material can be made of carbon steel/manganese steel, Yangzhou Zhongmei multi-way valve, Boli hydraulic cylinder, Hefei Wanli oil pump, Japanese Valqua seal, Bonwe hydraulic oil pipe, German Siemens PLC control system, Flashlight integrated operation mode, two-way peristaltic compression function, with cab operation, standard garbage turning bucket or hanging bucket turning board.

03. Advantages of a pure electric garbage compactor truck

1. The collection method is simple: a change of the messy and old appearance of trash cans all over the streets in the city, and secondary pollution.

2. Large loading capacity: The compression garbage truck has the functions of automatic repeated compression and peristaltic compression, with a high compression ratio and good sealing performance. The loading capacity is equivalent to twice that of ordinary garbage trucks of the same ton.

3. Automated operation: using a computer control system, all loading and unloading only needs to be operated by one driver, which not only reduces the labor intensity of sanitation workers but also improves the working environment.

4. Good economy: When the equipment is working, the computer control system automatically controls the throttle.

5. Double insurance system: The operating system has dual functions of computer control and manual operation to ensure and improve the utilization rate of the vehicle.

6. Turning mechanism: optional turning mechanism with a trash can (or bucket).

7. Safe work: equipped with night work lights, convenient for sanitation workers to work at night.

04. The function of a pure electric garbage compactor truck

1. The U-shaped integrally formed truss slot with high strength of Japanese technology is used as the movable guide rail of the garbage pushing plate, which has strong pressure resistance and good deformation resistance.

2. The main components such as the trash can are made of high-strength weather-resistant steel plates, and are designed in an arc shape, which is simple and beautiful, has a large effective volume, outstanding overall structural performance, and strong impact resistance.

3. Equipped with a large-capacity sewage tank, combined with a diversion sewage collection device, and equipped with a flexible and reliable sewage tank cleaning door sealing device, which effectively prevents secondary pollution caused by sewage leakage.

4. The sliding block of the push plate is made of high wear resistance alloy material, which has a long service life.

5. Equipped with a two-way compression function, high compression efficiency, and large garbage loading capacity.

6. Elaborately designed lifting support device for easy installation and long service life, high efficiency, and wide application cam clamping device for bucket mechanism, effectively eliminating the risk of bucket dropping during the feeding process.

05. Pure electric garbage compactor truck video