A new type of sanitation vehicle specially used for garbage collection and transportation. It adopts mechatronics-hydraulic integrated control technology. With the help of mechanical, electrical, and hydraulic combined automatic control and control systems, the garbage can be dumped in through special devices such as carriages, fillers, and push plates. , Crushing or flattening, strong loading, squeezing the garbage into the trash can, compacting and pushing unloading, its main characteristics are simple and efficient garbage collection, with automatic repeated compression and peristaltic compression function, high compression ratio, large loading capacity, high degree of job automation. It mainly collects and transports urban domestic garbage, and can collect bulk wastes of urban residents. It is an ideal garbage collection and vehicle for urban sanitation departments, factories, mines, and docks.

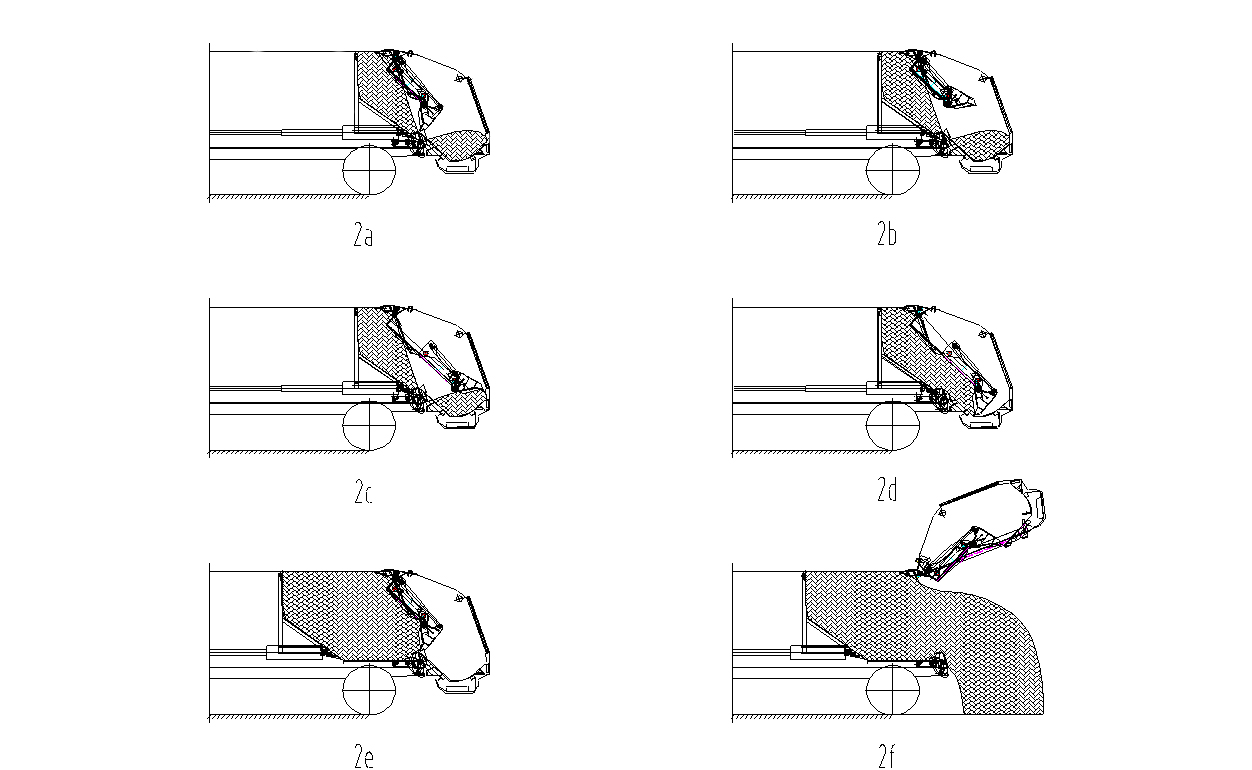

1. Put bagged, bulk, or barreled garbage into the loading hopper, as shown in Figure 2a.

2. The scraper on the filler is turned up, as shown in Figure 2b.

3. The sliding plate on the filler goes down, as shown in Figure 2c.

4. The scraper is pressed down to crush and squeeze the garbage, as shown in Figure 2d.

5. The skateboard moves upwards, compresses, and squeezes the garbage into the gap between the fixed plate and the push plate, as shown in Figure 2e. In this way, a garbage filling operation is completed, that is, a garbage pressure-filling cycle and the garbage pressure-filling device is at the start of the next garbage pressure-filling cycle, which is the waiting state.

When loading garbage, the push plate is pushed into place first, and then the garbage is loaded. Because the oil cylinder of the push plate mechanism has a certain back pressure, the push plate retracts resistance. Only when the squeezing force of the rubbish is greater than the resistance of the push plate, the push plate can be used. It will retract before the garbage can enter the garbage bin, so when the garbage enters the garbage bin from the filler, it will be initially compacted and distributed evenly. The garbage is continuously loaded so that the push plate is continuously retracted into position, and the garbage is further compacted in the process.

6. After the garbage is full, the vehicle is transported to the garbage transfer station or treatment site, the filler is turned on, and the push plate mechanism pushes backward to push the garbage out of the garbage bin. After the garbage is unloaded, the push plate should be retracted in time. And locked the filler, completed garbage collection and transportation work. As shown in Figure 2f.