The rear load garbage truck is composed of a sealed garbage compartment, a hydraulic system, and an operating system. The whole vehicle is fully sealed, and all the sewage from the compression, dumping, and compression process enters the sewage tank, which completely solves the problem of secondary pollution during garbage transportation and avoids inconvenience to people. The key components are adopted Imported components have the advantages of high pressure, good sealing, convenient operation, safety, etc., and can be equipped with a rear hanging bucket turning mechanism or a garbage bucket turning mechanism.

1. Multi-directional pictures

2. Chassis configuration

Dongfeng Tianjin chassis, white semi-cab, Cummins 210 horsepower, Fast small eight-speed gearbox, 4700mm wheelbase, 10.00 steel tires, original air conditioning, electric glass windows, airbag seats, driving recorder, cruise, electronic Throttle, central control lock, air brake, remote control key, ABS, rotary, front axle 5 tons, rear axle 10 tons, double-layer girder, clutch assist, exhaust brake.

3. Bodywork configuration

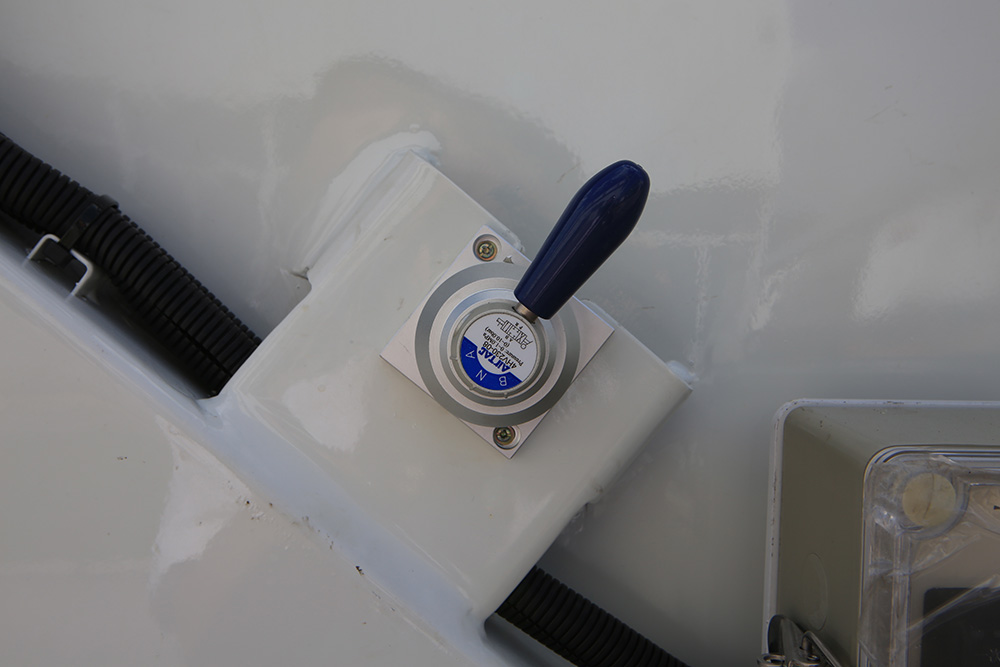

The volume of the compartment is 15 cubic meters, made of 6mm high-quality carbon steel sheet, the elliptical tank body, the inside of the tank body is treated with anti-corrosion, vacuum suction pump (optional oil ring pump and water ring pump), oil and gas separator and water vapor separator are installed, Level gauge, anti-overflow valve, a 360-degree rotatable boom frame is installed on the top, and a butterfly valve drain at the rear. Supporting reinforcement plate at the bottom, two-way compression, developed easy-to-clean sewage tank, integrated flashlight operation mode, dual electronic controls on both sides, operable in the cab, optional PLC electronic control system, rear turning mechanism iron bucket or rubber bucket, and swing arm Type turning mechanism.

4. Outstanding features

(1) The method of garbage collection is simple: change the messy and old appearance of garbage cans all over the streets in the city, and prevent secondary pollution.

(2) Large loading capacity: The maximum crushing pressure is up to 12 tons, and the loading capacity is equivalent to two and a half times of the same ton of non-compressed garbage.

(3) Operation automation: The computer control system is adopted. During all loading and unloading operations, one driver is required to operate. Two operation modes, fully automatic and semi-automatic can be set, which not only reduces the labor intensity of sanitation workers but also greatly improves the working environment.

(4) Good economy: When the special equipment is working, the computer control system automatically controls the throttle.

(5) Double insurance system: The operating system has the dual functions of computer control and manual operation, which greatly guarantees and improves the utilization rate of the vehicle.

(6) Turnover mechanism: An optional turnaround mechanism with a trash can (or bucket) can be installed.

5. Development Trend

(1) Garbage monitoring system: During the work of the rear load garbage truck, the garbage loading situation is the change in the garbage truckload that the manager cares about and whether the garbage in the garbage bin is full. Under normal circumstances, it is difficult to monitor. By loading the garbage monitoring system, it can detect the change of the vehicle load and whether the garbage is full at any time and anywhere, providing a reference for the garbage truck drivers and managers. This is conducive to improving the scientific nature of garbage truck operation and driving safety? At the same time, it can also reduce the workload of staff and improve work efficiency.

(2) Bucket tipping mechanism: The bucket tipping mechanism equipped with fully automatic control is a new direction for the development of rear load garbage trucks. It can easily realize automatic grabbing, lifting, and unloading of large and small trash bins in different positions.

(3) Hydraulic control device: The hydraulic device of the rear load garbage truck should have the following characteristics: oil flow (such as LS control) is required to be provided; smaller throttle loss: reduce pipeline connection work: no leakage: can be combined with other hydraulic The combination of functions, such as the hydraulic pump of the loading mechanism, can supply oil to the grasping tongs and other systems.

(4) Deodorization and sterilization: The application of deodorization and sterilization technology in compressed garbage trucks is also a development direction. Eliminating the spread of bacteria and reducing odor pollution has become a top priority. Some ozone deodorization and sterilization technologies have been successfully used in such products.

(6) Separated compartment: The internal structure of the compressed garbage truck body can be divided into several parts according to a certain proportion. This structural division allows the compressed garbage truck to collect and separate several different types of garbage during the same operation. The garbage collection route can be optimized to provide more convenience for garbage sorting and recycling.

6. Work video