The FULONGMA compression garbage truck is composed of two parts: a second-class automobile chassis and a special working device. It is a new type of special sanitation vehicle dedicated to collecting and transporting garbage. It mainly collects and transports urban household garbage and can collect bulk waste from urban residents. It is an ideal garbage collection and vehicle for urban sanitation departments, factories, mines, and docks.

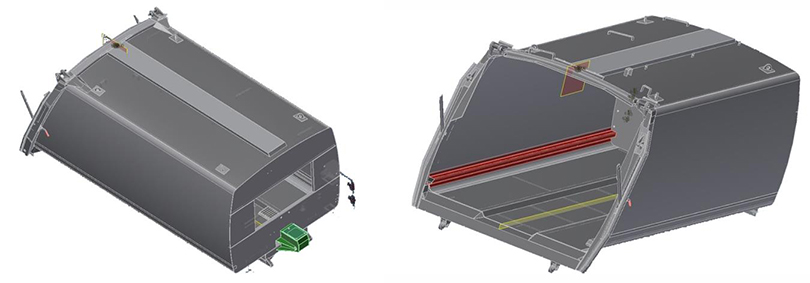

1. Trash can

The main components such as the trash can are made of high-quality high-strength weather-resistant steel sheet produced by Shanghai Baosteel, which is sprayed, and phosphate after pickling, which has strong corrosion resistance. The shape adopts the arc design, which is simple and beautiful, the effective volume is large, the overall structural performance is outstanding, and the impact resistance is strong. Used for loading crushed and compacted garbage. The trash bin is equipped with a two-way compression function, which has high compression efficiency and large garbage loading capacity. When unloading, after the filler is lifted in place, the scraper and slide plate automatically realize a cycle to remove the garbage remaining in the filler.

The U-shaped integrally formed truss slot with high strength of Japanese technology is used as the movable guide rail of the garbage pushing plate, which has strong pressure resistance and good deformation resistance.

The main components such as trash bins are made of B480GNQR high-strength weather-resistant steel plate produced by Shanghai Baosteel and adopt the curved design, which is simple and beautiful, large effective volume, outstanding overall structural performance, and strong impact resistance.

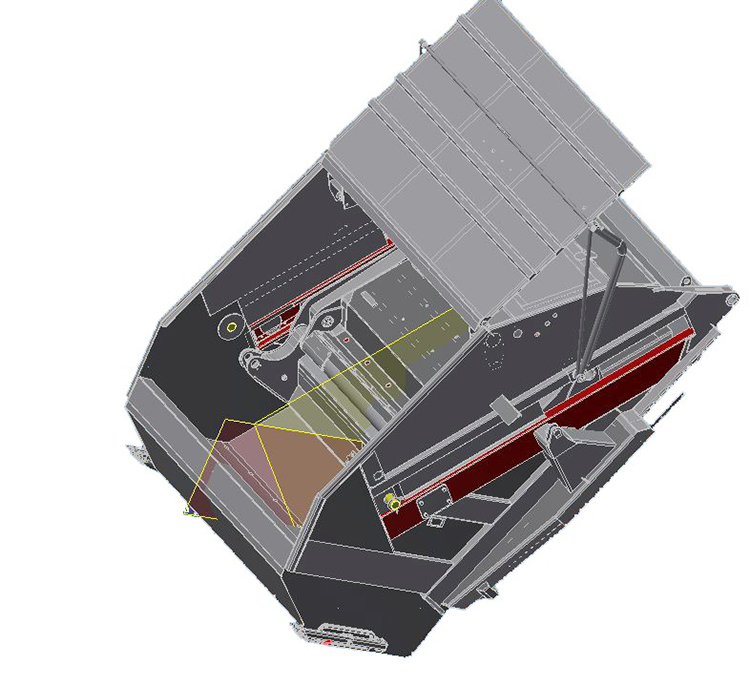

2. Filler

It consists of a loading hopper, a scraper, a sliding plate, a fixed plate, a sliding block, and other parts, which are used to complete the garbage crushing, compaction, and press the dense garbage into the garbage bin. Equipped with a two-way compression function, high compression efficiency, and large garbage loading capacity.

When unloading, after the filler is lifted in place, the scraper and slide plate automatically realize a cycle to remove the garbage remaining in the filler. A sealing cover plate is set at the opening. The opening and closing of the cover plate are pneumatically controlled, which is easy to operate and can effectively prevent the secondary pollution of garbage and odor. Besides, the joint between the filler and the box body adopts adjustable hydraulic locking and full sealing technology, which has good sealing performance.

It is equipped with multiple safety protection measures such as an interlock switch to prevent the filler from falling, a safety brace, and a self-locking function of the filler lifting cylinder. At the same time, it is equipped with a safety rod for secondary protection, which is safe and reliable. Ensure the safety of operators and improve work safety.

A sealing cover plate is set at the opening of the filler. The opening and closing of the cover plate are pneumatically controlled, and the operation is light, which can effectively prevent the secondary pollution of garbage and odor. (National patented technology, patent number: ZL 2010 2 0185523.5 movable rear cover of the garbage truck filler)

Equipped with a large-capacity sewage tank, combined with a diversion type sewage collection device, the sewage that leaks between the filler and the garbage bin body due to the failure of the sealing strip can be diverted to the special sewage collection tank, effectively preventing the leakage of sewage Secondary pollution.

The joint between the filler and the box body adopts adjustable hydraulic locking and full sealing technology, which has good sealing performance.

There are multiple safety protection measures such as the sliding board up and the scraper up button, the emergency stop button, the interlock switch to prevent the filler from falling, the safety brace, and the self-locking function of the filler lifting cylinder to ensure the safety of personnel.

3. Push plate mechanism

The push plate mechanism is located in the trash bin and can slide along the side guide rails. The push plate movable guide adopts the high-strength U-shaped integrally formed truss slot of Japanese technology. As the movable guide of the garbage push plate, it has strong pressure resistance and good deformation resistance. The sliding block of the push plate is made of high wear resistance alloy material, which has a long service life.

4. Wastewater tank

It is equipped with a large-capacity sewage tank. The sewage tank is acid-washed and then sprayed with phosphating treatment. It has high corrosion resistance. Combined with the diversion sewage collection device, the diversion sewage collection device is adopted, which can combine the filler and the garbage box body. The sewage that leaks due to the failure of the sealing strip is drained to the special sewage collection box, which effectively prevents secondary pollution caused by sewage leakage.

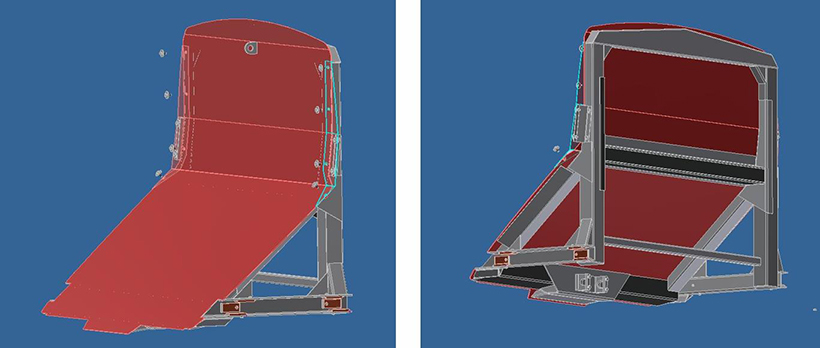

5. Lifting mechanism

A variety of special lifting mechanisms are optional to adapt to different front-end garbage collection forms. The lifting mechanism is made of high-strength steel and is sprayed after pickling, which has strong corrosion resistance. Optimized design of lifting mechanism, beautiful and simple appearance.

6. Hydraulic system

It is composed of power take-off, gear oil pump, multi-way valve, throttle valve, hydraulic cylinder, oil tank, oil filter, pipeline, etc., used to push scraper, sliding plate, push plate, and filler to complete various operations.

The selection of hydraulic components is the famous brand products imported from abroad or domestic well-known enterprises to ensure excellent performance and reliable work.

The pipeline adapts the technology of “ferrule type cone sealing”, which has a good anti-vibration effect and high sealing reliability.

The hydraulic hose adopts a high wear-resistant and pressure-resistant hose with superior performance and low loss.

At the same time, the inner surface of the hydraulic pipeline adopts acid washing, high-pressure washing, air blowing, and other cycles of washing treatment processes before assembly to ensure a high degree of cleanliness of the oil circuit.

7. Electrical control system

The electric control system adopts the electric control method, and the control system is composed of a changeover switch, a non-contact travel switch, a waterproof button, a controller, an automatic throttle device, and a circuit.

The front control box is located in the cab, and the rear control box is located at the left rear of the filler.

The electrical control components and controllers are all foreign brand-name products to ensure the stability of the entire electrical control system.

Equipped with automatic and manual dual control modes, it can control the garbage truck operation in the driver’s cab, the middle of the carriage, and the rear of the carriage, which is convenient and efficient.